I’m going to talk you through what a pillar drill is, what they’re used for, and how they differ from other types of drills.

Once you get to the end of the guide, you’ll know everything there is to know. So, let’s jump in!

Contents (Jump to Topic)

What Is A Pillar Drill & What Is It Used For?

Put simply, a pillar drill is a powerful sliding drill mounted on a metal column with a clamp. The height of the drill can be adjusted with a rotating handle, whilst the clamp holds the object in place.

Typically the clamp can be angled, which allows the user to get accurate holes in any direction.

In most cases, a pillar drill will sit standalone on the floor, but there are smaller versions of a pillar drill, which are referred to as either a drill press or bench drill. However, at some point or other, you may hear all of them being referred to as pillar drills.

Unlike a bench drill which is movable and for use on a workbench. A pillar drill is a free-standing machine, with the column (or pillar) being attached to a base plate that is bolted or securely fixed to the floor. Hence the name ‘Pillar Drill’.

What Does The Pillar Do On The Pillar Drill?

It is the pillar that allows the drill mechanism to be raised and lowered (using a rotating handle).

This allows you to work with thicker and bulkier items. But it also means that the size & type of material you work with the most will denote the size of the machine you require.

So, What Does A Pillar Drill Do & It’s Uses?

Put simply a pillar drill will drill consistent and precise holes in various materials. Ensuring that each hole is not only dead square horizontally but to a specific depth that you require.

An induction motor is used to rotate a drill bit while the sliding column is adjusted with the aid of a rotating handle. This adjustment handle is used to execute the precise drilling depth required.

A pillar drill may have to cope with high load situations and for this reason, they are fitted with high-quality, long-lasting drill bits. In addition to that, they have their own work table (usually tilting) to which you secure the component being drilled.

This ensures both efficiency and drilling accuracy are maintained with every hole drilled.

The capabilities and versatility of this type of machine drill mean that you will find them used in a wide range of industries, including metalworking, construction, and woodworking.

In addition to the wide range of industries, this tool is also frequently used for a large variety of workshop tasks, including buffing, sharpening, and polishing. All of which, can be done by simply swapping out drill bits for the appropriate rotating accessories.

Who, When & Where Was It Invented?

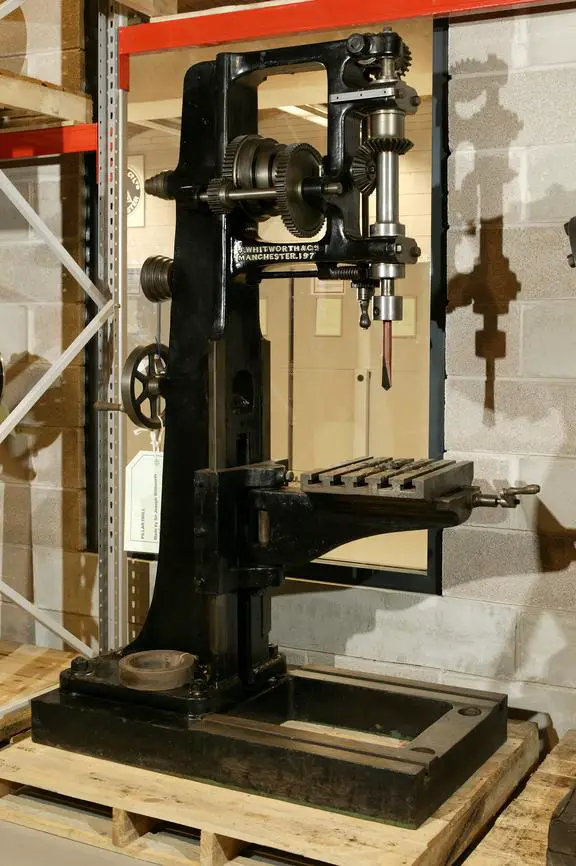

Developed by Joseph Whitworth & Company, the first-ever power-driven pillar drill came about in 1847. At which the power source was connected to the drill bit via bevel gears. Whitworth drills were described in the 1854 Encyclopedia of Useful Arts as “… one of the most complete tools of the kind ever constructed”.

Image source: sciencemuseumgroup.org

Later on, this machine was donated to the museum in the year 1974 by The University of Manchester’s Engineering Department.

What Materials Can A Pillar Drill Drill Into?

You are probably aware that different types of materials pose different problems when drilling into them.

For example, it is practically impossible to get an exact 90-degree hole in metal with a handheld drill. Whereas with wood, especially if you are a tradesman, this is not as hard to achieve.

However, doing time and time again with the same certainty can pose a problem.

Here are some of the different materials that a pillar drill can drill into:

- Wood (plywood, hardwood, and softwood timber)

- Metal, aluminum, and steel

- Acrylic (petroleum-based thermoplastics)

- Plastic

- Sheet material

Remember, having the right drill bit for the material is imperative, as is the speed that you set the drill to.

What Are The Benefits Of Pillar Drills Over Handheld Drills?

Whether it be a free-standing or a benchtop pillar drill, there is one main difference to handheld drills.

And, that is whether the project is taken to the table or the tool to the project. In other words, a pillar drill cannot be used to drill holes in the wall, fix wooden cabinets, or tighten screws, etc.

Again, the other big difference is the precision and accuracy that can be achieved when using a bench drill.

In many industries, such as aerospace, it is necessary for millions of perfectly measured, quality holes to be drilled. Because during the assembly process, it is important to minimize crack growth and maintain the reliability of the material. (Ok, so that may not be the best of examples but I’m sure you get it, this is where a pillar drill comes in handy).

When using a pillar drill you have full control of the different speeds, up to maximum power (RPM), needed for each of the materials to be drilled. In addition to that, because you can set the drill depth to the millimeter you are able to drill multiple holes with the precise depths and angle each time.

So what are the advantages of pillar drills when compared to hand-held drills?

Benefits Of Using A Pillar Drill:

- Accuracy and precision

- Can be used to drill metal safely and efficiently

- Is capable of handling heavy-duty tasks

- You have full control over the speed

Benefits Of Using A Hand-Held Drill:

- Lightweight and easily taken from site to site

- Requires less storage space

- Great for general DIY work

- Can drill a material at different angles with ease

What Is The Difference Between A Pillar Drill & A Drill Press?

Both pillar drill and the drill press are commonly used to refer to the same drilling equipment.However, as I said earlier this is a common misconception.

There is actually a big difference, one is floor standing while the other is used on a workbench.

Not to be confused with a bench drill, which is also very similar. A bench drill is permanently fixed into place whereas a pillar drill press can be more portable.

And with that said, you’ve pretty much learned everything you need to know about pillar drills. They’re quite simple machines, but serve a very important purpose in the world of engineering and manufacturing. But before you run out and buy one, let’s quickly run through some do’s and don’ts to keep you safe.

Important Safety Precautions When Using A Pillar Drill

When using any machinery or power tool safety should always be at the top of your priority list. Here I have put together a list of important safety precautions from the Department of Mechanical & Industrial Engineering that should be adhered to when operating a pillar drill.

1. Wear Appropriate Safety Gear

It goes without saying that wearing adequate protection against dust and small particles is of the utmost importance. Safety goggles, gloves, masks, and appropriate clothing should always be worn when using machinery.

2. Check the Emergency Stop Button

Before you start check that the emergency stop button is working correctly. You never know when you may need it.

3. Close Chuck Guard

Always use the safety guards that are fitted to the machine, they are there for a reason. Trying to take shortcuts may cause serious injury.

4. Tuck In Clothing, Roll Back Sleeves & Tie Long Hair Back

Avoid wearing loose clothing and always tie long hair back. Looking fashionable and cool is not what the workplace is for, even if you are only a DIYer.

5. Clamp Workpiece In Suitable Vice

Always ensure that you use the clamp provided to hold your workpiece on the table, never try to handhold it. Should you let go the results can be very serious.

6. Know How To Turn The Machine Off

Before beginning to use a machine, it is critical that the user understands how the machine can be turned off. This is not only just in case of a mishap but to avoid a mishap happening to another person that doesn’t realize the machine is on.

Final Thoughts

Although a pillar drill is a considered purchase and relatively large in size, it will help you achieve professional results.

The range of different sizes makes these machines useful not only in the workshop but, for keen DIY woodworkers and metalworkers too.

The most important thing to remember is when it comes to these machines, size isn’t everything, let your needs choose the right tool for you.

People Also Ask (FAQ)

Welcome to the Frequently Asked Questions (FAQs) section. Here you will find the answers to the commonly asked questions.

What are the dangers of a pillar drill?

Although few, there are some dangers when using a pillar drill. Mainly it is damage to eyes from swarf and dust when safety goggles are not worn and hand injuries from spinning materials that have not been clamped securely.

What does a chuck guard do?

A chuck guard is fitted to a pillar drill to provide users with protection from flying debris. When the drill is in use all sorts of swarf and shards can be thrown out, including snapped drill bits that may cause injury.

How is a radial arm drilling machine different from a pillar drill?

The distance between the drill head and the column in a pillar drill machine is fixed, whereas the distance between the drill head and the column (the radius) in a radial drill machine can be adjusted to some extent, i.e. pushed/pulled, rotated etc.